In-Tank Urethane Metering and Dispensing | Industry Leading Packaging Equipment Manufacturer

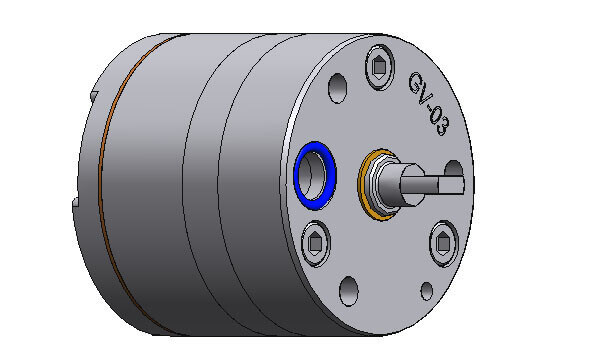

Benefits & Features:

- Ultra wear resistant IGR pump element

- Oversized durable journal bearings

- Suitable for closed loop (pressure) operation

- Tang drive

- Integrated safety burst plug

- Integrated inlet screen

- Proprietary coating process

- Tens of thousands in service

Select Performance Parameters

| Fluid | Polyol and Isocynate Chemicals |

| Fluid Viscosity Range (cSt) | 30 - 10,000 |

| Displacement (cc/rev) | 1.0 |

| Operating Speed (rpm) | 0 - 2,500 |

| Pressure Rise, Maximum (bar) | 50 |

| Operating Life (years) | 5 |

| Size (in) | 2.19 D x 2.0 L |

| Weight (lb) | 1.5 |