Circulation of Transformer Oil for Gas-Chromatography Based Monitoring | Utility Service Company

Benefits & Features

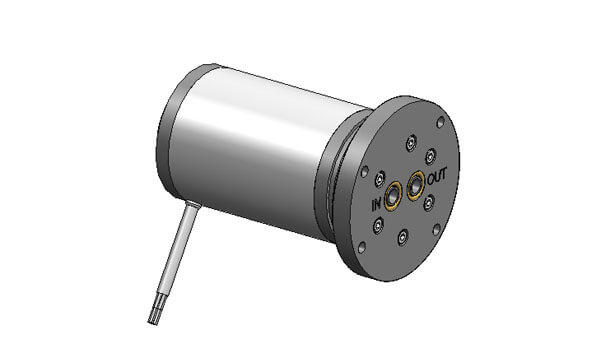

This brushless DC motor driven pump was designed to operate at low speed and mount directly to our customer’s equipment in order to minimize fluid turbulence that could effect the results of their state of the art gas chromatography technology. The circulating transformer oil is monitored for trace gases that indicate impending transformer failure.

- Canned rotor design which eliminates the rotary shaft seal and the possibility of leaks

- Manifold mount

- 8-pole neodymium brushless DC motor for a long maintenance-free life

- Rotor speed feedback that can be used for closed-loop servo control

- Hardened steel shaft supported by journal bearings

- Housings machined from heat treated aluminum alloy

- Teflon impregnated hard anodized finish for superior corrosion protection and durability in harsh environments

- Integral 24-Vdc brushless dc drive motor

Select Performance Parameters

| Operating Voltage, Nominal (Volts) | 24 |

| Working Fluid | Transformer Oils (e.g. Shell Diala AX) |

| Operating Speed, Nominal (rpm) | 750 |

| Flow Rate, Nominal (cc/min) | 250 |

| Pressure Rise (psid) | 50 |

| Temperature Range (°C) | -15°C to +120 |

| Operating Life (hours) | 40,000 |

| Weight (lb) | 2.5 |

| Size (in) | 3.0 D x 4.5 L |