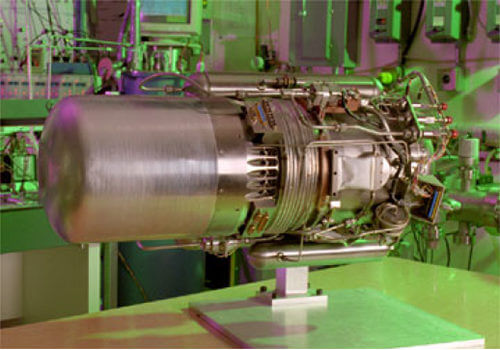

Lubrication and Sealing for Satellite-Based Cryogenic Compressor | Satellite Technology Integrator

Benefits & Features

This unique pump has eight inlets to integrate with the customer’s unique zero-g oil collection system and is designed to operate at very low input speeds.

- Ultra-high reliability for extended operation in orbit

- Hardened steel housings

- Tool steel pump gears

- Two independent circuits, four pressure regulated flows

- Integrated pressure regulating valves

Select Performance Parameters

| Pump Speed (rpm) | 200 |

| Operating Fluid | Polyalphaolefin |

| Fluid Temperature Range (°F) | 0 to 200 |

| Circuit Output Flow, Maximum (cc/min) | 29 |

| Circuit Ouput Pressure Rise, Maximum (psid) | 800 |

| Operating Life, Continuos (years) | 10 |

For Cryogenic Compressor

Coolant Pump, Made in the USA