Chemical Metering and Dispensing | Industrial Adhesive Applicator Equipment Manufacturer

Benefits & Features

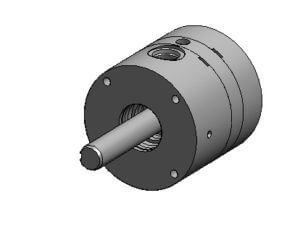

This Cascon pump was designed to provide a cost-effective solution for metering and dispensing a wide variety of fluids used for caulking, joint and crack filling, sealants and adhesives. Cascon engineers worked closely with the customer to optimize mounting, fluid interconnect and system maintenance.

- Nickel Plated Cast-Iron Housings

- Proprietary Coating Process for Extended Wear Resistance

- Hardened AISI 8620 Steel Shaft

- Suitable for Coupling, Gear, or Pulley Drive

- Hardened Sintered Metal Gerotor Pumping Element

Select Performance Parameters

| Fluid Type | Isocyanates & Polyols Urethanes, Silicones & Epoxies |

| Displacement (in3/revolution) | 0.59 and 1.18 |

| Pump Speed (rpm) | 20 - 1,000 |

| Pressure Rise, Maximum (psid) | 750 |

| Fluid Temperature Range (°F) | 20 - 250 |

| Duty Cycle | Continuous & cycling |

| Size (in) | 3.75 D x 4.1 L |

| Weight (lb) | ~10 |