Chemical Metering and Dispensing | Manufacturer of Roofing Equipment

Benefits & Features

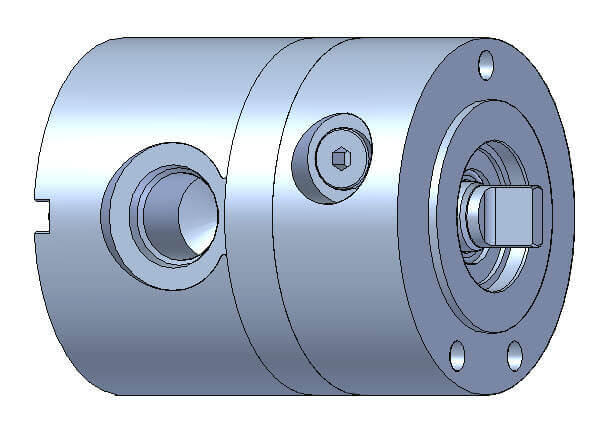

Cascon designed this gerotor metering pump for dispensing the two component adhesive at a precise 1:1 ratio. The design included a through-drive arrangement so two pumps could be bolted back-to-back and driven by a single electric motor thereby reducing the size and cost of the customer’s system. Designed, manufactured and tested in the USA.

- Through-Drive for Tandem Mounting and Single Electric Motor Drive

- Hardened AISI 8620 Steel Shaft

- Teflon Impregnated, Electroless Nickel Plated Housing for Superior Wear and Corrosion Protection

- Integral Pressure Relief Valve

- Hardened Sintered Metal Gerotor Pumping Element

Select Performance Parameters

| Fluids | Two-Component Urethanes |

| Fluid Viscosity Range (cSt) | 20 - 10,000 |

| Displacement (cc/rev) | 10 |

| Operating Speed, Nominal (rpm) | 300 |

| Pressure Rise, Nominal (psid) | 300 |

| Temperature Range (°F) | 0 - 150 |

| Size (in) | 3.25 D x 3.9 L |

| Weight, Single Pump (lb) | 6.9 |