Cascon adds thermal cycling capability

Our laboratory in Yarmouth, Maine is operated in accordance with ANSI/ESD S20.20 for electrostatic discharge (ESD) protection and NAS412 for foreign object damage (FOD) prevention. Many of our aerospace products are assembled, tested and shipped from our Yarmouth facility. Design verification and failure analysis activities also occur here.

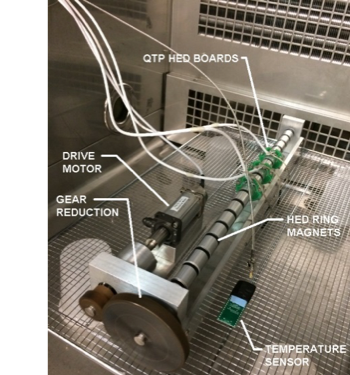

Cascon recently added thermal cycling to our list of capabilities. Our fully automated Espec ESZ-2C thermal chamber is capable of cycling between -70 and 180 °C and is used for a variety of design verification and acceptance test tasks. We verify the capability and reliability of our pump controls by testing the designs to their limits and beyond. Some of our most critical aerospace products require substantial thermal cycling during the acceptance testing process for each unit. This new capability allows us to reduce the overall length of the development cycle, and save our customers money.