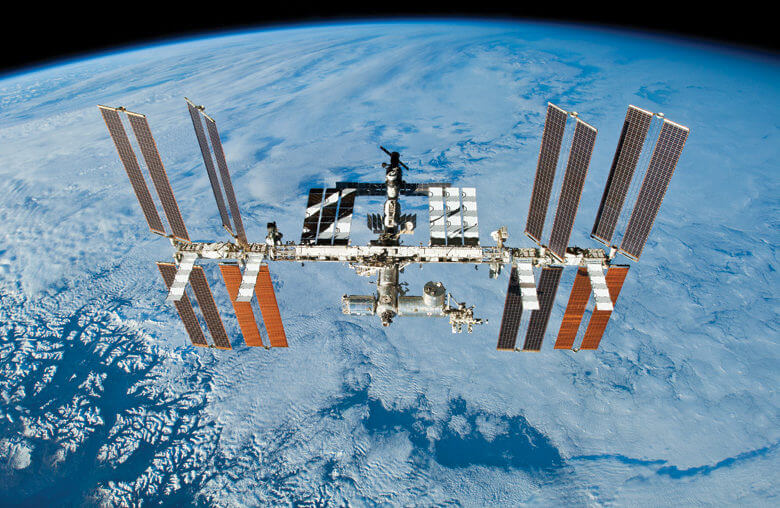

Environmental System Support Aboard the International Space Station (ISS) | Leading Supplier of Spacecraft Environmental Systems

Benefits & Features

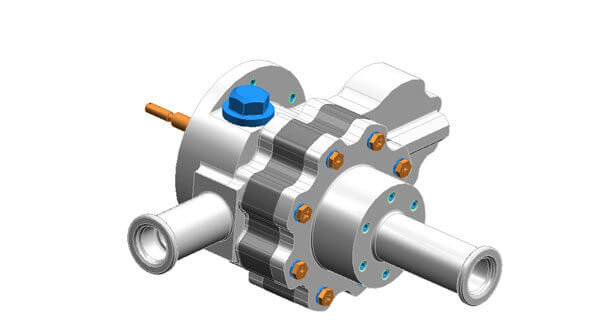

This ceramic spur gear pump was designed to allow variants to support three environmental systems on the ISS: oxygen generation (OGA system), water delivery (WPDP system), and waste water processing (WWP system). The highly engineered solution provides the exceptional reliability and long operating life required of space-based equipment; service calls are problematic. Designed with common parts and processes these pumps featured:

- Zirconia pump gears

- Stellite drive shafts

- Ceramic side plates

- 316 stainless steel housings

- Silicon-carbide journal bearings

- Complete traceability and documentation to support NASA program standards

- Zero-G operation

This ECLSS NASA Fact sheet provides an overview of the system which is located on Node 3 of the ISS.

Select Performance Parameters

| Fluid | Deionized Water (OGA & WPDP), Grey Waste Water (WWP) |

| Pump Speed, Nominal (rpm) | 2,500 |

| Pressure Rise (psid) | 30 (OGA & WPDP models), 110 (WWP model) |

| Flow (in3/minute) | 330 (OGA & WPDP models), 20 (WWP model) |

| Vibration & Shock | Typical Spacecraft Launch Loads |