Bearing Lubrication and Scavenge for FT8 Power Turbine | Leading Gas Turbine Engine Manufacturer

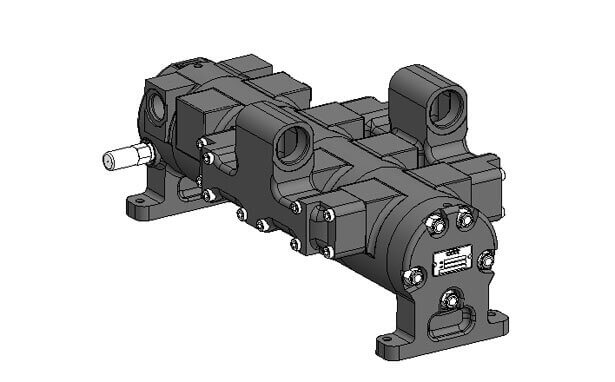

Benefits & Features

The extended operating life of this aero-derivative machine meant that the lubrication system would need to compensate for seal wear over tens of thousands of run hours. Capable of managing a 30:1 air-to-oil ratio and fluid temperatures above 300 °F, this multi-circuit pump now supports hundreds of electrical generation and mechanical drive installations around the world.

- Durable ductile cast-iron casings

- Reliable gerotor technology

- Case-hardened steel pump elements

- Single hardened steel shaft

- Integral relief valve

- Capable of high air-to-oil scavenge ratios

Select Performance Parameters

| Working Fluid | Synthetic Turbine Oil (e.g., MIL-PRF-23699, MIL-PRF-7808 |

| Operating Speed, 50/60 Hz (rpm) | 2,950/3,600 |

| Lubrication Flow @ 2,950 rpm (gpm) | 14.5 |

| Lubrication Pressure Rise (psid) | 100 |

| Scavenge #1 Capacity @ 2,950 rpm (gpm) | 55 |

| Scavenge #2 Capacity @ 2,950 rpm (gpm) | 165 |

| Scavenge Pressure (psid) | 35 |

| Mean Time Between Overhaul (MTBO) | 40,000 hours |

| Size (in) | 11.0 W x 10.0 H x 25.0 L |

| Weight (lb) | 165 |