Cascon has decades of experience delivering pump and hydraulic motor solutions to mission critical applications. Whether a simple lubrication pump for a high-torque industrial gearbox or a complex coolant pump for a spacecraft environmental system, Cascon’s scalable processes can be adjusted to efficiently and effectively support your OEM needs.

We follow a rigorous-yet-flexible process for managing your technical and commercial requirements throughout the complete product lifecycle, from conception to full-rate production, and eventual obsolescence. We apply a progression of tools to insure performance, quality and reliability, whether your application requires one of our configure-to-order, engineer-to-order, or completely custom products. We work with companies that know their market and have the vision for a solution to serve it; if your solution involves a pump or related product that you can’t find in a catalog, we can help.

Product Design Requirements and Compliance Tracking

Cascon is your solution for the design, development, and production of pumps for specialty applications.

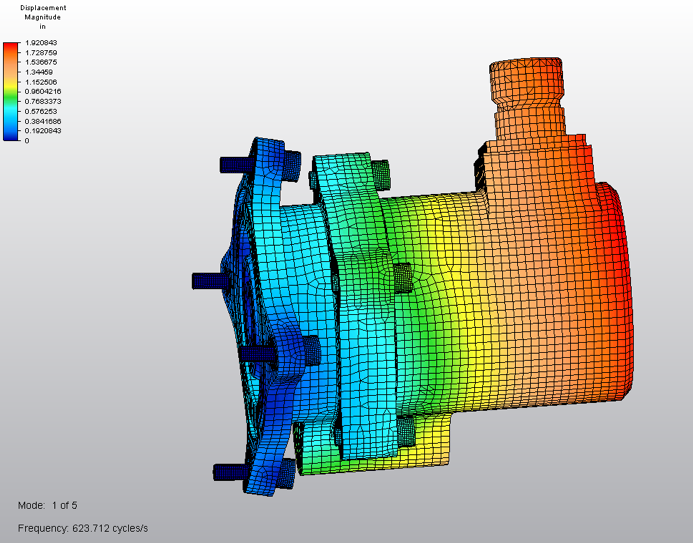

A combination of proprietary engineering and industry standard computer aided design (CAD), and computer aided engineering (CAE) tools support performance simulation of new product designs. This capability allows development of a “digital twin” to the eventual product you require. The behavior of this digital twin under varying conditions of input speed, pressure, temperature, physical loadings, etc., informs your overall system design, insures an optimum solution, and lays the groundwork for a smooth transition to physical pump hardware.

Natural Frequency

engineer (verb): to work artfully to bring something about. The product development cycle involves dozens of decisions, including materials, critical part clearances, surface finishes, selection of key subcomponents, consideration of manufacturing process alternatives, and more. This process, often carried out concurrently with Simulation activities, insures that the functional design elements of a new product (pump element, shaft bearings, pump casing, etc.) each do their job in supporting the overall design. We have brought hundreds of products through this cycle and use our experience to efficiently navigate this complex process as we bring a new custom product to life for your application.

We can tailor pre-existing designs to suit client specifications, delivering all the benefits of Cascon engineering without time-intensive development.

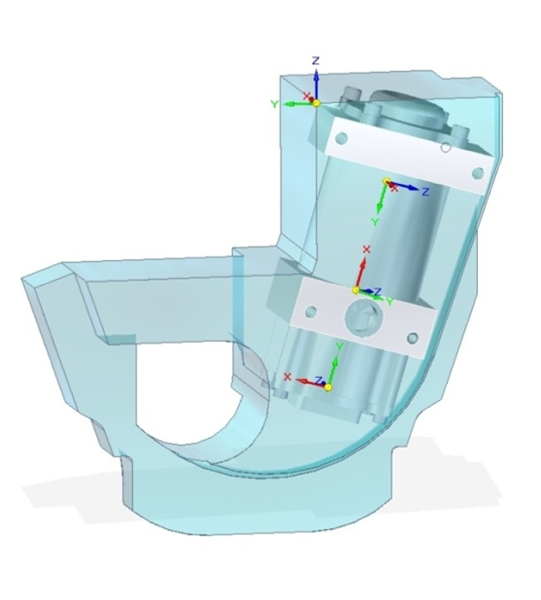

For fully custom products, Interface Design is the next step for bringing your new product to reality. For our engineer-to-order pump products, the simulation and engineering design work has previously been completed and design elements verified. Regardless, in this step we set out to make sure the pump product you need fits seamlessly into your OEM system design. This process can include working with your team to fit the new product into complex and challenging spaces, designing an input shaft spline, or selecting an appropriate electrical connector for one of our engineer-to-order electric drive pumps.

Fitting a New Aerospace Coolant Pump Design into the Available Space Envelope

Custom and engineer-to-order products often require the manufacture of a physical prototype to support verification and validation steps prior to production. We manufacture needed prototypes using equipment and processes representative of production so you can be confident in a smooth transition launch of your OEM product – and assured there will be no surprises.

Tried and tested designs allow us to begin at verification and production, greatly shortening delivery times.

Verification and validation are often used interchangeably, but we believe there are some meaningful differences. We’ve adopted the following common definitions:

Verification: the process of confirming that the design meets all its stated requirements (is the pump designed right?). For example, testing may be used to confirm that the pump provides 5 gallons of coolant per minute as specified in the design requirements. A verification plan can blend testing, inspection, and analysis to achieve the most cost-effective approach to making sure the design meets all requirements.

Validation: the process of confirming that the set of design requirements is complete and accurate (is the right pump designed?). For example, validation would include confirmation that 5 gallons per minute is adequate to keep your system cool under all its operating conditions.

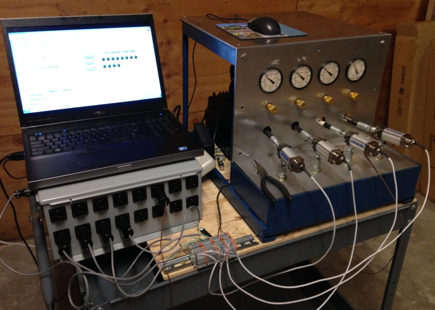

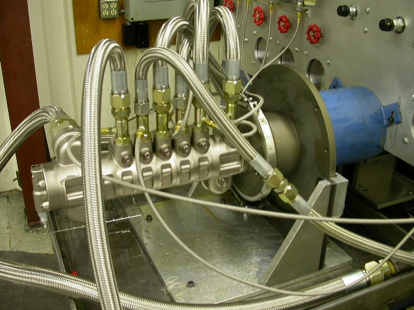

Verification can be largely be completed in a laboratory environment at Cascon, or one of a handful of subcontractors with whom we work closely. We may seek to confirm proper flow, pressure, input power, structural integrity, and tolerance of environmental conditions such as corrosion, vibration loads, shock loads, and electrical power quality. We routinely test to the requirements of RTCA DO-160, MIL-STD-461, and MIL-STD-810. Verification is a step that must be completed in the process of developing a new custom design. However, our engineer-to-order and configure-to-order products are based on designs that have already been largely verified, so if one of these product types suits your needs, design verification can be greatly simplified or even eliminated.

Validation is completed in your OEM system, whether an industrial machine, construction vehicle, or unmanned aerial vehicle. This is the final step necessary to insure the entire system works in concert, whether a CT Scanner, avionics cooling package, or a construction vehicle transmission.

Operating Life Verification with Galden Heat Transfer Fluid, Electric Coolant Pump

Flow and Pressure Verification Gas Turbine Lubrication and Scavenge Pump

Once satisfied that the new product design meets all the requirements needed to support your OEM application, Cascon and sister company Chamberlain Machine have the resources and experience to reliably supply your production needs.

We employ the latest in machine tool and manufacturing technology in our ISO 9001:2015 certified, 50,000 square-foot, state-of-the-art manufacturing facility located in Walpole, New Hampshire. An aggressive re-investment policy insures that we can provide the highest quality and lowest cost solution over the entire product lifecycle.

All our products are made in the USA. Cascon’s engineering and manufacturing resources are perfectly suited for production quantities of as little as 10 units, to more than 50 thousand per year. Our engineers support the manufacturing process throughout the lifecycle of the product.

Production acceptance testing insures that our products can be assembled directly into customer equipment without additional incoming inspection or test. We have the necessary document, material, and process control procedures in place to certify our products and provide objective evidence of compliance with contract and regulatory specifications.

As both the designer and manufacturer, Cascon assumes full responsibility for meeting all technical and quality assurance requirements, whether the work is performed within our own facility or by one of our sub-tier sources. Cascon’s attention to detail, customer service, and ultimate accountability is evident in every pump, motor, and gear we ship.

Cascon stays with you over the entire product lifecycle to supply the pump or hydraulic motor your OEM product requires. We’ll be there to help with inventory management, product improvements, value engineering efforts, and managing eventual obsolescence. It’s not uncommon for our customer relationships to span twenty years or more as we support a single pump product.