A legacy of service, innovation, and performance.

At Cascon, we measure our success as much by the relationships we’ve formed and maintained with our OEM customers as by the quality of the pumps we design and produce. In nearly every case, those relationships thrive on a combination of open communication and collaboration. So whether we’re engaged to design a custom pump for a unique application, to configure a Cascon design to specific OEM requirements, or to reproduce one of our field-proven pumps, we start by listening – then we leverage our shared knowledge to achieve innovative, cost-effective solutions.

Our roots run deep in the technology needed to deliver the very best pump solutions. Since 1988, Cascon has worked with customers who are technology leaders in their respective industries. Whether developing a solution for a truck axle or transmission, oil & gas exploration equipment, or a spacecraft environmental system, we have never missed an opportunity to learn. We can leverage this unique technical knowledge to bring the very best pump solution to your OEM product.

Throughout the lifecycle of each OEM product, the Cascon team provides ongoing technical support and service, while working to maintain close communication at every step of the process. We also take care to provide ongoing support, making sure the production pump’s performance measures up to its promise.

Where We Work

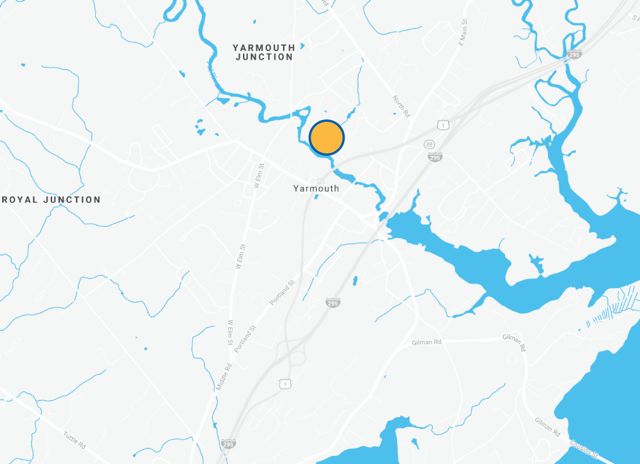

Founded in 1988, Cascon is an ISO9001:2015 certified company headquartered in the coastal town of Yarmouth, Maine. Our modern facility houses the company’s sales, customer service, engineering and product development functions. Final assembly and test of many of our aerospace products are also completed in this facility.

Our employees make the most of our surroundings, taking advantage of all four seasons to cycle, ski, hike and enjoy the outdoors. Given our appreciation for Maine’s natural beauty, we’ve demonstrated our commitment to the environment by installing approximately 25kW of solar panels on our Yarmouth facility. The panels produce almost 35,000kWh of energy each year to provide most of our office and laboratory electrical demand – and offset nearly 36,000 lbs. of carbon pollution.

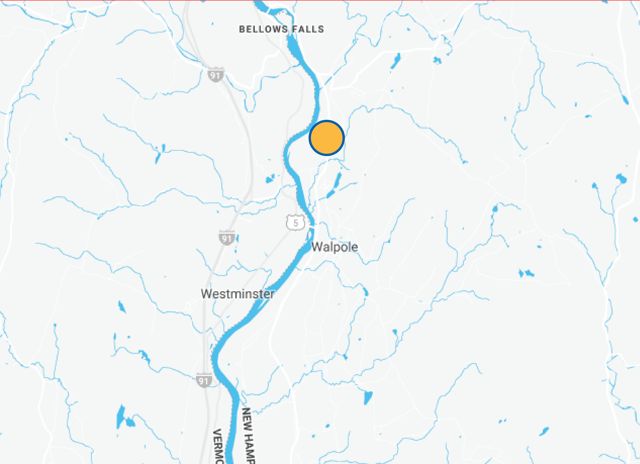

Primary manufacturing is completed at our sister facility, Chamberlain Machine, in Walpole, New Hampshire, a 50,000 square foot state-of-the-art manufacturing plant. Products destined for markets other than aerospace are assembled, tested and shipped directly from this facility. Approximately 1/3 of the electrical load of this facility is also serviced with an on-site solar array.